LulzBot's Open-Source FRESH-Certified Bio Printer

June 08, 2023

Important Update

Before getting too excited about this product announcement, please see our other blog post about LulzBot’s questionable future.

Last week, 3D Universe was invited to be a part of a select group of resellers who attended the LulzBot Bio Summit in Loveland, Colorado to get a first peek at the amazing, LulzBot Bio 3D printers being produced by Aleph Objects, Inc. (the company behind the LulzBot product line).

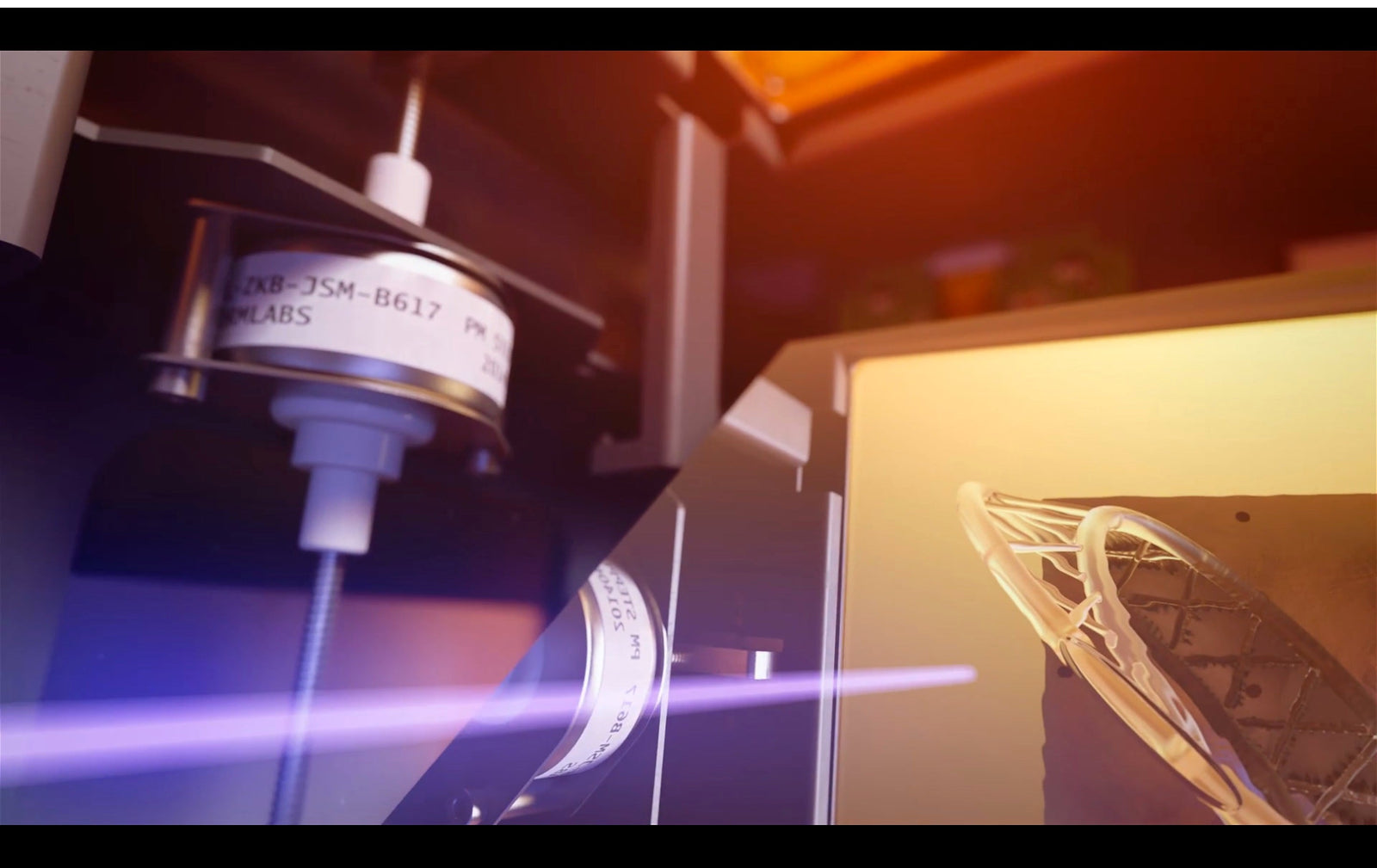

We were treated to a behind-the-scenes look at how these bioprinters work, took a tour of their R&D facility and got to pass around a dish of 3D printed arteries. (We may have also gotten to witness the look on one of our fellow reseller’s faces as they accidentally dumped that dish of 3D printed arteries all over the table, which would have made for a fun video to include, but alas, we failed to get that footage for you!)

The “Heart” of the LulzBot Bio

The LulzBot Bio enables 3D printing with materials such as unmodified collagen, bioinks, and other soft materials, and has already been instrumental in 3D printing the first-ever fully functional human heart tissue.

“What we’ve shown is that we can print pieces of the heart out of cells and collagen into parts that truly function, like a heart valve or a small beating ventricle. By using MRI data of a human heart, we were able to accurately reproduce patient-specific anatomical structure and 3D bioprint collagen and human heart cells.”

Adam Feinberg, professor of biomedical engineering (BME) and materials science & engineering at Carnegie Mellon.

Imagine a World Without Organ Transplant Lists

While we are a ways from being able to bioprint functional organs for transplants, it is exciting to see so many advancements taking place in labs all over the world as well as in universities and STEM based classrooms.

Watching 3D printed tissues come to life and beat or “breathe” is nothing less than mind-blowing.

“3D bioprinting is an innovative mix of 3D printing and tissue engineering. Imagine a world without organ transplant lists, where the donor is the recipient of their own 3D printed organ. This is one of the key drivers of the technology. Blood vessels, skin and simple organs are already being made in the lab today.

– Chad Coarsey, Director of Operations, The Bionic Glove Project

With the refinement of methods, the bounds of bioprinting are unending. The next focus will aim to bioprint more of the complex important organs such as liver and kidneys, increase the use of ex vivo cancer and disease models for testing, and develop the next generation of cell and tissue based 3D technology.”

STEM Education and Bioprinting in the Classroom

It is no secret that we here at 3D Universe are passionate about getting 3D printing into more STEM based learning environments. Putting this kind of technology within reach of our future changemakers is imperative.

Whether it is basic 3D printing, laser cutting or bioprinting being used in k-12 classrooms, these tools, when placed into the hands of students who still do not know what is impossible yet, have the potential to catapult us into a completely new era of change that we have only dreamed about in science fiction stories.

The LulzBot Bio is going to help teachers and professors take their curriculums to the next level and allow even more hands-on learning, not only at the university levels but also for middle and high school students.

“Bio printing stands to be a great tool that could be employed for STEM education, yet still requires a degree of a learning curve and subject matter knowledge to get there. With proper instruction and facilitation, I can see this getting adopted at the high school level and eventually at other levels of education.”

– Chad Coarsey, Director of Operations, The Bionic Glove Project

The LulzBot Bio Offers a Platform for Quality and Versatility

With a legacy of manufacturing high-quality 3D printers spanning nearly a decade, LulzBot brings its award-winning print quality to the bioprinting market with the LulzBot Bio, its first-ever Fluid Deposition Fabrication (FDF) 3D printer.

Unlike its pneumatic counterparts, the Bio’s syringe pump system allows for precise stopping and retraction, preventing unintentional extrusion and stringing while printing intricate models like vasculature. Its easily-modified, Open Source design removes proprietary restrictions, providing a versatile platform for innovation that grows with ever-changing discoveries and advancements.

“For researchers, you don’t know what materials or processes you’ll be using in 6 months, let alone one year from now. You need hardware that can be adjusted quickly and easily, without proprietary restrictions.”

Grant Flaharty, Aleph Objects CEO and President.

The LulzBot Bio 3D printers come with nearly everything needed to start bioprinting, including extensively tested, preconfigured material profiles in Cura LulzBot Edition. See the full list of features, specifications, and what’s included here.

Collagen: The Human Body’s Major Structural Protein

Collagen is prominent in biological structures, making collagen bioinks one of the most promising materials for bioprinting applications. However, it has proven extremely difficult to 3D print in its unmodified form. The LulzBot Bio enables printing with unmodified collagen using the FRESH 2.0 method. Developed and refined by the Regenerative Biomaterials & Therapeutics Group at Carnegie Mellon University, FRESH bioprinting uses thermoreversible support gels to hold soft materials during printing. The temporary support gel is dissolved, leaving the print intact.

“Other bioprinting techniques often require materials to be chemically altered or mixed with other materials to make them 3D printable. Because of the excellent biocompatibility of collagen, being able to 3D print with it in its original form brings us that much closer to recreating models that mimic human physiology.”

Steven Abadie, Aleph Objects CTO

Bioprinted Tissues for Faster, Safer Innovation with the LulzBot Bio

Bioprinting is revolutionizing pharmaceutical development, cosmetic testing, tissue engineering, and regenerative medicine. This technology can be used to recreate physiology to study disease, determine the effectiveness and potential side effects of new drugs in development, and provide skin tissue models for cosmetic testing.

Bringing a new drug to market with current methods costs around $ 2.5 billion USD and can take more than a decade from start to finish. The probability of success is less than 10-15% despite promising results in early stages with animal testing, as the absence of toxicity in animals is a poor predictor of efficacy in humans. The development of 3D bioprinting provides a more human-relevant alternative in both pharmaceutical and cosmetic testing. To date, over 40 countries worldwide have banned or restricted animal testing on cosmetics and cosmetic ingredients, which has accelerated the development of bioprinted human tissue for cosmetic development.

“Bioprinting also offers an unforeseen advantage to pharmaceutical testing. When testing new cancer drugs, bio printers can use tissue scaffolds to make “ex vivo” cancer organ models for drug testing. It allows more drugs to be tested quicker and gets them to the right patients without the need to use untested, potentially dangerous drugs on those patients.”

– Chad Coarsey, Director of Operations, The Bionic Glove Project

An Extensive Range of Applications

The open-source design of the FRESH Certified LulzBot Bio opens up a world of exciting possibilities across a range of industries. Here are just some of the possible use cases:

-

Pharmaceutical & cosmetic testing –

- In vitro (in a test tube) testing aims to reduce failure rate (currently 90%+) of bringing drugs to market (costs ~$2.5b in 2018) by testing on bioprinted tissues in pre-clinical testing. The goal is to reduce failure when moving to phase 3 (clinical) trials (estimated 50% failure rate in clinical trials).

- Can be used to recreate physiology to study disease.

- Testing on kidney and liver cells are of particular importance.

-

Tissue Engineering – The practice of combining scaffolds, cells, and biologically active molecules into functional tissues.

- Long term goal of bioprinting human organs.

- Regenerative Medicine – The process of replacing, engineering or regenerating human cells, tissues or organs to restore or establish normal function.

- Education – The bio is expected to be extremely impactful for teaching life sciences in K-12.

No other desktop 3D bioprinter can match the value and capabilities of the LulzBot Bio:

- Able to print unmodified collagen and other soft materials. Other bioprinting techniques often require chemical alteration or mixing of materials to enable / improve ‘printability’.

- Hardware / software is easily configurable for new materials and processes.

- Open material format. No proprietary materials.

- More affordable than most market options.

- Bigger maximum print area than most competitors. The compact design easily fits within laminar flow cabinets or tissue culture hoods.

- LulzBot has a long-standing reputation for exceptional print quality. Print quality is said to match or exceed $100k+ machines.

- Some of the best print quality for FFF style bioprinters.

- Improved print quality by an order of a magnitude over Fresh 1.0 (250 μm to 20 μm)

- Comes with a generous supply (50g) of Sodium Alginate (this material alone would cost up to $32,000 from other companies)

- Syringe pump system enables printing of highly intricate structures such as blood vessels and artery trees

- Better control of stopping / retraction which reduces oozing.

- Pneumatic systems only have positive pressure and near zero pressure.

- For pneumatic systems, the pressure required to extrude materials is not linear and variable based on the amount of material in the system.

- It is speculated that some of the pneumatic systems on the market lack adequate pressure to dispense highly viscous materials.

We are really excited to see where this technology takes us! If you are interested in more information about the LulzBot Bio, please email us at support@3duniverse.org for more information or give us a call!

The LulzBot Bio is coming soon, with availability projected for late 2019.