How long will my 3D printing filament last?

December 18, 2025

Quick Reference: Filament Shelf Life

| Filament Type | Unopened (Vacuum Sealed) | Opened (Exposed to Air) | Vulnerability |

| PLA / Tough PLA | 2–3 Years | 1–3 Months* | Becomes brittle and snaps easily. |

| PETG | 2–3 Years | 3–6 Months* | Absorbs water; causes stringing/blobs. |

| ABS / ASA | 3–5+ Years | 6–12 Months | Fairly stable; moisture causes bubbles. |

| TPU (Flexible) | 2 Years | 2–4 Weeks | Prints become foamy and lose clarity. |

| Nylon (PA) | 1–2 Years | 12–24 Hours | Extremely thirsty; absorbs water instantly. |

| Polycarbonate (PC) | 1–2 Years | 24–48 Hours | Similar to Nylon; degrades rapidly. |

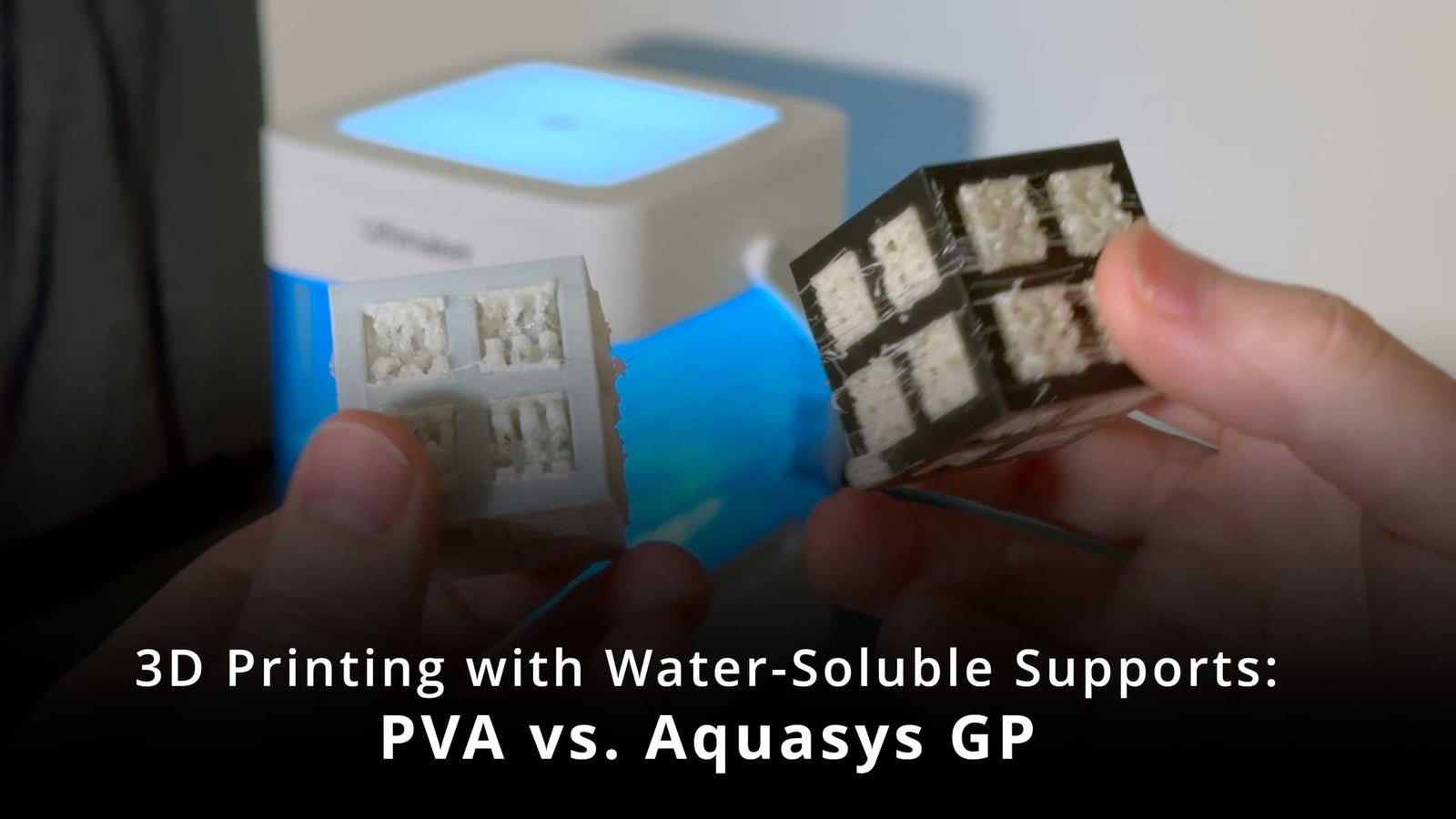

| PVA (Support) | 1 Year | < 12 Hours | Dissolves in water; ruined very fast. |

1. Common Filaments (PLA, Tough PLA, PETG)

These are the most forgiving materials, but they fail in different ways.

-

PLA / Tough PLA: The primary sign of "expired" PLA is brittlenessWhile moisture causes some print quality issues, the bigger problem is that the filament physically snaps.If you try to unspool an old roll of PLA and it shatters like dry spaghetti, it has absorbed moisture.

-

Revival: Dry at 45°C–50°C for 4–6 hours.

-

-

PETG: Unlike PLA, PETG rarely snaps. Instead, it just prints poorly. You will notice excessive "stringing" (fine cobwebs everywhere) and a rough, matte finish instead of a glossy one.

-

Revival: Dry at 60°C–65°C for 4–6 hours.

-

2. Durable Filaments (ABS, ASA)

These are petroleum-based and naturally more resistant to water than plant-based PLA.

-

Longevity: You can often leave a spool of ABS on a shelf for a year and still get a decent print, though it may pop or hiss slightly.

-

ASA Note: ASA is UV-resistant, meaning it is the only filament that can be stored on a windowsill in direct sunlight without degrading. All other filaments will become weak and discolored if exposed to UV light for months.

-

Revival: Dry at 80°C–85°C for 4 hours.

-

3. High-Performance & Soluble (Nylon, PC, PVA, TPU)

These materials are "sponges." They should never be stored exposed to air, even for a few days.

-

Nylon & Polycarbonate: These can absorb enough water in a single day to ruin a print. Water turns to steam in the nozzle, blasting holes in your layers and reducing part strength by up to 50%.

-

PVA: This is water-soluble support material. If left out, it becomes soft, sticky, and eventually will jam your extruder permanently.

-

TPU: When wet, flexible filaments print with a "foamy" texture and lose their layer adhesion.

-

Revival: These almost always require active drying before every use. Dry Nylon/PC at 70°C+ and TPU at 50°C–55°C

-

Storage Best Practices

The "Golden Standard" for Storage

-

Vacuum Seal: If you aren't using a spool for more than a week, put it back in a vacuum bag.

-

Desiccant: Always include a fresh packet of silica gel inside the bag.

-

Darkness: Store bags in an opaque box or cupboard to prevent UV degradation.

The "Active Use" Solution (Dry Boxes)

If you print frequently, vacuum sealing every time is tedious. Build or buy a Dry Box:

-

Use a sealed plastic tote (like a gasket-sealed cereal container).

-

Fill the bottom with rechargeable color-changing silica beads.

-

Feed the filament directly from the box to the printer via a PTFE tube.

-

Result: You can leave filaments like Nylon or PLA in these boxes for months without degradation.