Benefits of Pairing a Vacuum Former with a 3D Printer

June 08, 2023

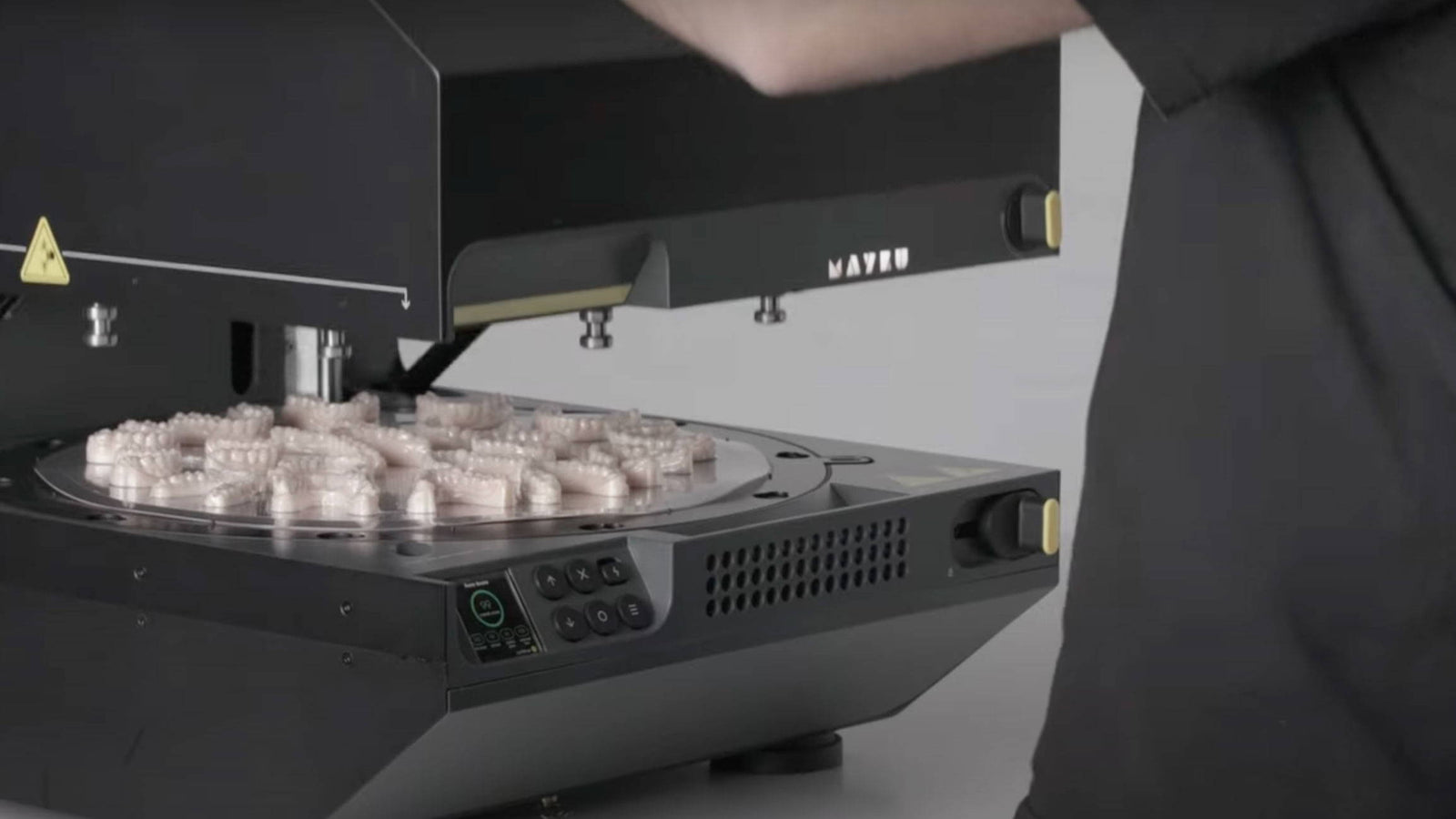

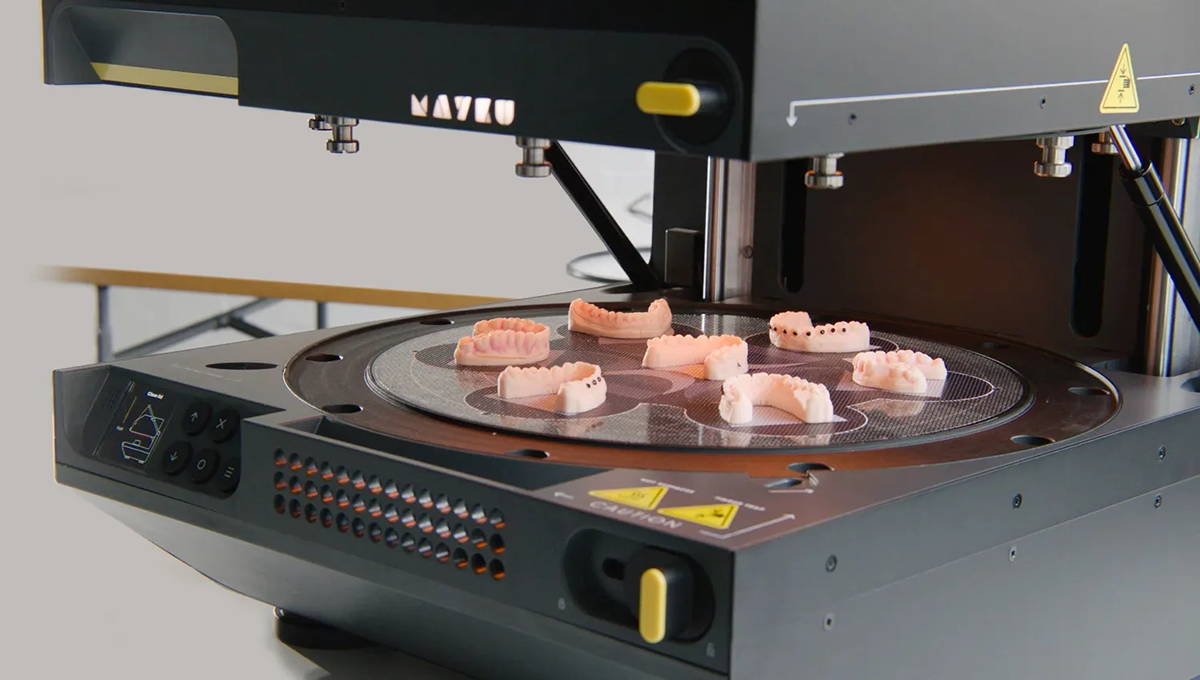

A 3D printer paired with a vacuum former can create objects with intricate shapes and details that would be otherwise difficult or impossible to create with either technology alone. The vacuum former can create negative molds of 3D-printed objects, which can then be used to create positive copies out of a variety of materials. This pairing of technologies opens up a world of possibilities for creating customized, one-of-a-kind objects.

Whether you are a chocolatier or chef looking to make unique designs for your tasty treats, an artist designing custom soaps, candles, and ceramics or you are needing lightweight casings for electronics, auto or aerospace companies, and more, using a 3D printer combined with a vacuum former gives you a whole new way to replicate your designs for a low cost.

What is Vacuum Forming?

A vacuum former is a type of plastic-forming machine that uses a vacuum to suck heated plastic sheets around a form to create a mold. The form used to create the mold can be 3D printed, hardened clay, glass, cardboard, sturdy food objects, found objects from nature (shells etc) or reused objects and much more as long as they do not have an overhang.

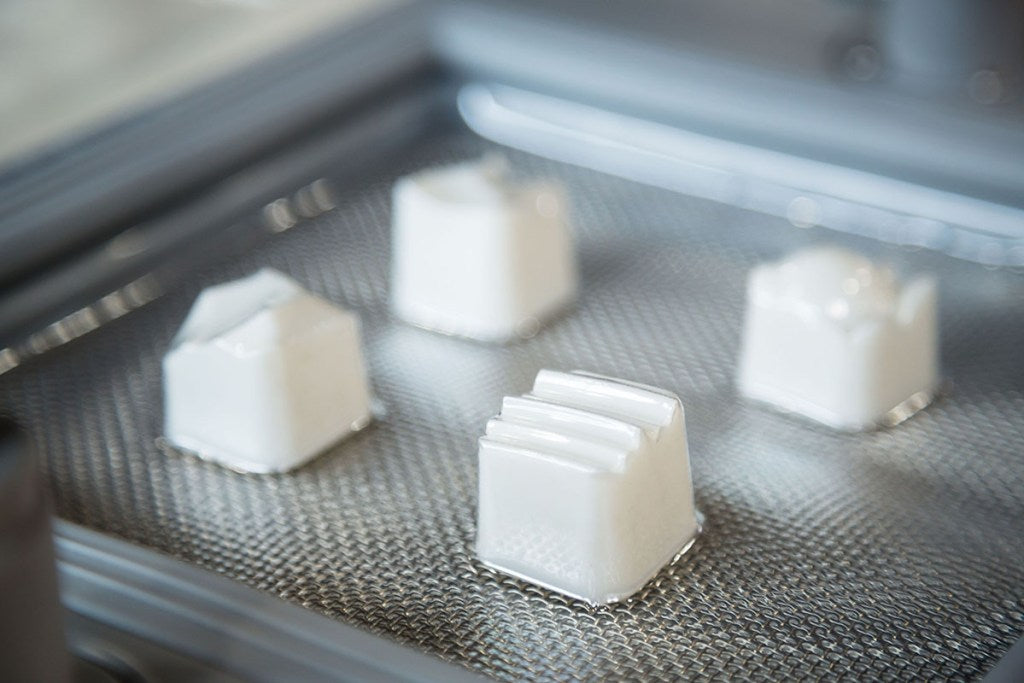

Once you have placed your form onto the bed of the vacuum former, it then heats the plastic sheet until it is soft and pliable. Once ready to form, the sheet is lowered and draped across the form and a vacuum sucks the heated plastic into a tight seal around the form to create a mold of the original object.

The plastic cools and hardens into the shape of the original form and creates a mold that can then be used to fill with chocolate, clay, resin, plaster, jesmonite, concrete, gelatin, soap, candle wax and much more to replicate the shape.

The vacuum former can be used to create complex shapes that would be difficult or impossible to create with other methods. It is also relatively fast, low cost, and simple for adults as well as younger children and students.

Overall, vacuum forming is a versatile and easy-to-use method for quickly replicating and creating complex shapes out of plastic.

How a Vacuum Former Can Improve Production Throughput

3D printers have become indispensable tools across a multitude of industries. They are providing strong competitive advantages by allowing organizations to iterate new designs much more rapidly and cost-effectively than ever before.

When printing a single part or prototype, a 3D printer is a perfect solution, allowing organizations to avoid costly and time-consuming outsourcing for parts production. But when dozens of copies are needed, the speed of a 3D printer can become a challenge. This is especially true in educational environments where teachers struggle to ensure all students have sufficient access to the available 3D printers.

By adding a desktop vacuum former into the mix, you can vastly improve the throughput for producing multiple copies of 3D-printed parts. After 3D printing a single copy of a part, it can be duplicated in a matter of seconds using vacuum-forming technology. In this way, a vacuum former can significantly increase the utility of a small number of 3D printers, allowing parts to be produced much more rapidly than with 3D printing alone.

Why are 3D Printed Models Preferred for Use with a Vacuum Former?

3D printed forms are often preferred over other materials when it comes to vacuum forming because they are more accurate, durable, solid, and versatile. With 3D printed forms, you can create vacuum-formed parts with better dimensional accuracy and repeatability, especially when you make your original design from heat-resistant materials so they do not warp or become brittle with multiple uses.

If a 3D printed model is created with FDM (Fused Deposition Modeling) 3D printers, they may need to be sanded or treated in an acetone bath to smooth them and remove lines from layers that may show up in the vacuum-formed mold.

During the design process, it is easy to create a form with a draft angle so the form can be easily removed from the mold, round corners to reduce the chance of webbing, and allow for including vent holes to ensure that the details of the design have ample suction from the vacuum below to pull the heated plastic into those areas.

Once you have designed your first form and tested your first vacuum-formed mold, it is easy to increase or decrease the size of the original, and make changes to the draft angles, corners, and vent holes in a matter of minutes. If you need to make an adjustment or simply want to offer a variety of different sizes of your finished product you simply resend your design to the 3D printer and make another form.

A Wide Variety of Applications for Vacuum Forming with 3D Printed Forms

Vacuum forming is very well known for its use as packaging for products, but there are dozens of other ways in which vacuum forming is being used. Below are a few examples of how vacuum forming is providing lower-cost options and easier solutions for various industries and educational institutions.

• Protective cases

• Interior panels and trims for aerospace and automotive applications

• Food, candy, and chocolate molds

• Seed trays and flower tubs in the agricultural industry

• Signage

• Lighting covers, panels, and diffusers

• Consumer electronic enclosures

• Movie, television, and cosplay props

• Medical equipment and enclosures

• Architectural models

• Model making for cars, boats, aircraft miniatures

• Soap and candle molds

• Art projects

• Ceramic and plaster molds

• Molds for pet treats and bird feeders

• Silicone mold making

• Costume design

• Educational projects for the classroom

• Much, much more!

Learn More about 3D Printers and Vacuum Formers

For more information about desktop 3D printers and vacuum formers, please visit our website.

We have a variety of 3D printers to choose from and will help you decide the best option for your home, business or classroom needs as well as information on which types of vacuum forming sheets you will need for your personal or business projects.

We also offer educational discounts on a variety of our 3D printers and the Mayku FormBox Vacuum former so please make sure to mention that you are an educator if you are searching for digital fabrication and vacuum forming tech for your school and classroom!