Benefits of Thermoforming in Business and Education

November 21, 2023

Introduction to Thermoforming Technology with the Mayku Multiplier

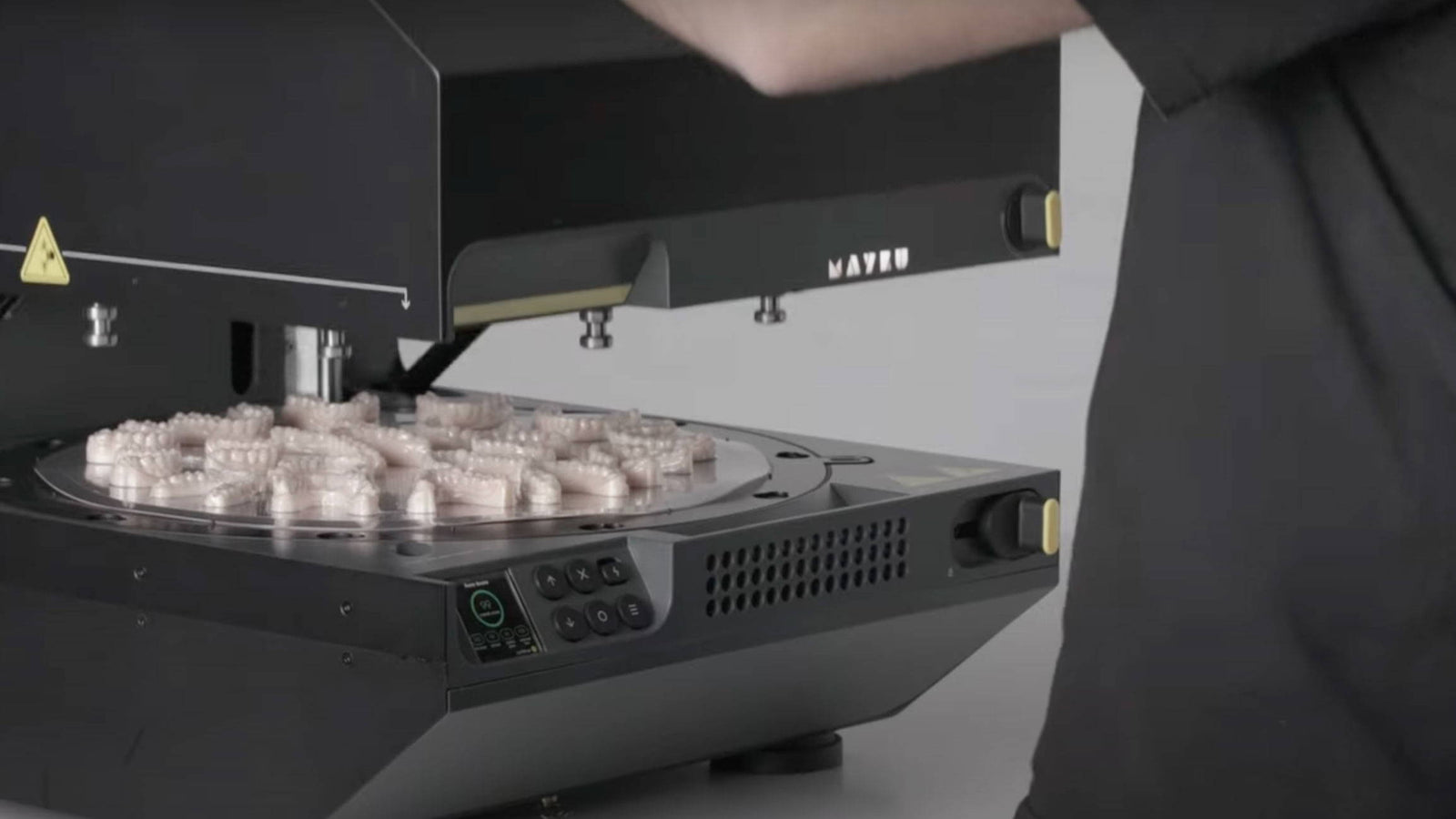

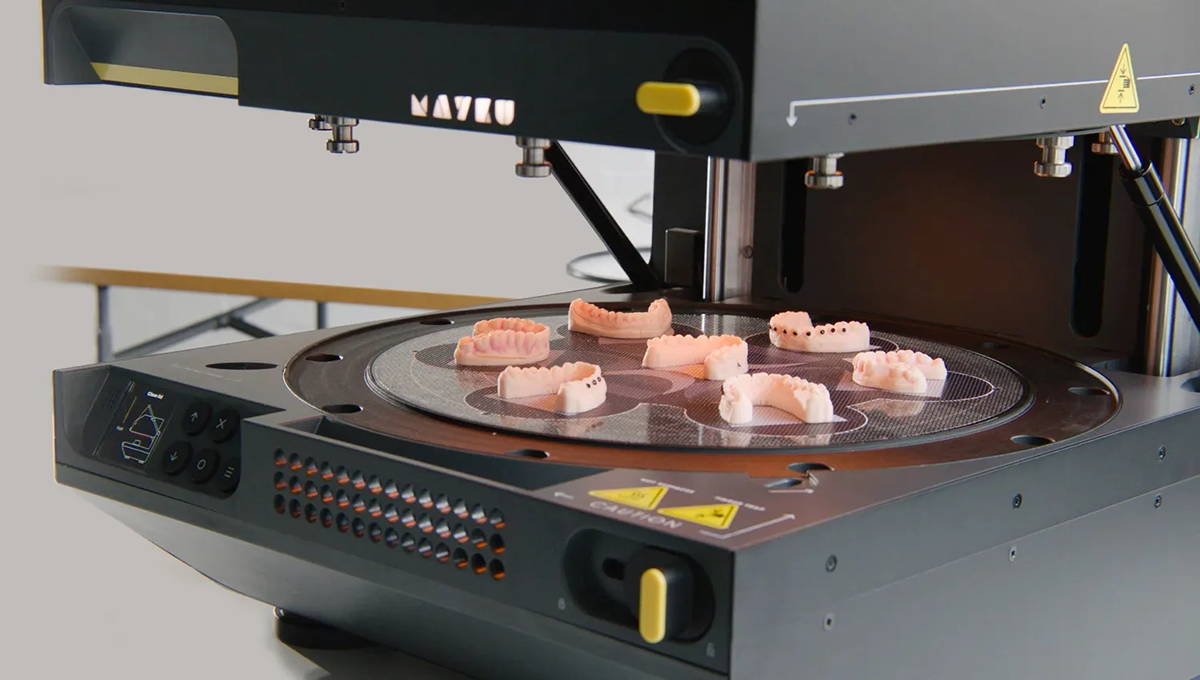

Thermoforming, specifically pressure forming, is a transformative technology for manufacturing detailed molds and parts. This process shapes heated plastic sheets using air pressure and can produce results in minutes, making it ideal for mass production. The Mayku Multiplier, a desktop pressure former, offers this industrial-grade technology in a compact form. It's capable of working with materials up to 5 mm thick and heating them to 225°C, producing parts with less than 1μm resolution.

Using the Mayku Muliplier, you can produce copies of 3D printed parts using high-grade polymers that are more suitable for end-use products. This offers a powerful and affordable means of scaling up production.

Benefits in Food Mold Production

The Mayku Multiplier is particularly advantageous for food mold production. It allows for the in-house creation of highly detailed, cost-effective prototypes, enhancing efficiency and reducing production time. This technology produces food molds with high precision and quality, ensuring they meet required standards for optical clarity and other criteria. It also supports a wide range of materials, from transparent to rigid, suitable for food-grade applications.

Impact on Product Casings Manufacturing

For product casings, the Mayku Multiplier enables rapid prototyping and tooling validation, leading to a faster time to market. It offers a high level of detail, precise tolerances, and compatibility with various materials like ABS and PMMA. This technology significantly reduces production line disruption and costs, allowing for faster iteration cycles and improved material testing.

Use in Manufacturing Protective Covers

Pressure forming technology, exemplified by the Mayku Multiplier, is highly effective in creating protective covers in manufacturing and robotics industries. It minimizes machine downtime and repair expenses by enabling the rapid, on-demand production of robust, high-quality parts. The Multiplier's capacity to work with a variety of industrial-grade materials adds to its versatility in production environments.

Educational Applications of Thermoforming

In educational settings, the Mayku Multiplier facilitates hands-on learning and exposes students to real-world manufacturing processes. It enhances problem-solving skills and creativity, allowing students to produce both prototypes and end-use parts. This technology is easily integrated into existing educational workflows, especially alongside 3D printing, to provide a comprehensive manufacturing experience. Educational institutions like Kingston University, MIT Play Labs, and Coventry University are already utilizing the Multiplier to enhance their curriculums.

Teaching Faster, Cost Effective and Accessible Prosthetic Molding Techniques at Wimbledon College of Art

The University of the Arts London have four Multiplier pressure formers operating across four of their university sites in the capital.

We visited one of those sites, Wimbledon College of Art, who have been using the Multiplier and 1.5mm EVA sheets to save costs and reduce the time involved in student mold making projects.

Providing Students with Access to Pressure Forming Technology on the Benchtop at Bristol University

Pressure forming is increasingly being used by engineering professionals in diverse

industries from product design to aerospace and beyond. To prepare students for

industry and to explore the benefits of pressure forming, educational institutions

like MIT, Harvard and Bristol university are installing the Mayku Multiplier in their

workshops and labs to provide students with access to this powerful technology.

Rapidly Creating High-Detail Custom Molds with Forma Moulds

Forma Moulds are a UK based mold manufacturer that design, prototype and

develop molds for a vast swathe of different clients around the world like Hilton

hotels, Caterpillar and Grey Goose vodka. Their innovative approach to mold

making enables them to deliver specific client needs fast and affordably with

a small and nimble team utilizing the latest in 3D printing and pressure forming

technology.

Reducing Plastic Waste Through Prototyping Highly Detailed Parts

Reducing plastic usage in mass manufacturing is one of the most critical issues of our time. Solutions to this challenge begin at the prototyping stage, where design decisions are made that will resonate throughout the product's lifetime when it goes to market.

Designing the Multiplier with Teenage Engineering

Teenage Engineering is a consumer electronics company based in Stockholm, Sweden.

Back in the early stages of development of the Multiplier, when the first prototypes of the desktop pressure former were starting to make successful forms, Mayku got in contact with the team at Teenage Engineering to see if they would like to work on the industrial design and user interface of the machine. What transpired was a development process between London and Sweden in the midst of a global pandemic. We caught up with the team at Teenage Engineering to talk about the process...

Prototyping Product Casings for Faster Times to Market with Meta

In the fast paced, competitive world of VR headset manufacture, innovating

fast and staying on top of the latest tech is of key strategic importance to getting

ahead in this exciting new field.

At Meta, the virtual optical engineering team are responsible for the development

of the optical modules in their VR headsets.

Thermoforming is a heavily used technology in VR headset mass manufacture for

both optical modules and product casings. Engineers at Meta use the Multiplier

in their Reality Lab to test and optimize thermoforming settings before going to full

scale production.

The Future of Thermoforming in Business and Education

Thermoforming, particularly with devices like the Mayku Multiplier, is revolutionizing production and education. Its ability to rapidly produce high-quality parts and prototypes is invaluable for businesses and classrooms alike. By adopting this technology, organizations can not only optimize their manufacturing processes but also prepare students for future careers in various industries.

Schedule a Free Consultation to Learn More

If you’d like to learn more about how your organization might benefit from thermoforming with the Mayku Multiplier, consider booking a one-on-one Zoom meeting with Jeremy Simon, our founder and technical lead, for a free consultation! Click below to pick a day/time.