Revolutionizing the Dental Industry with the Mayku Multiplier

December 04, 2024

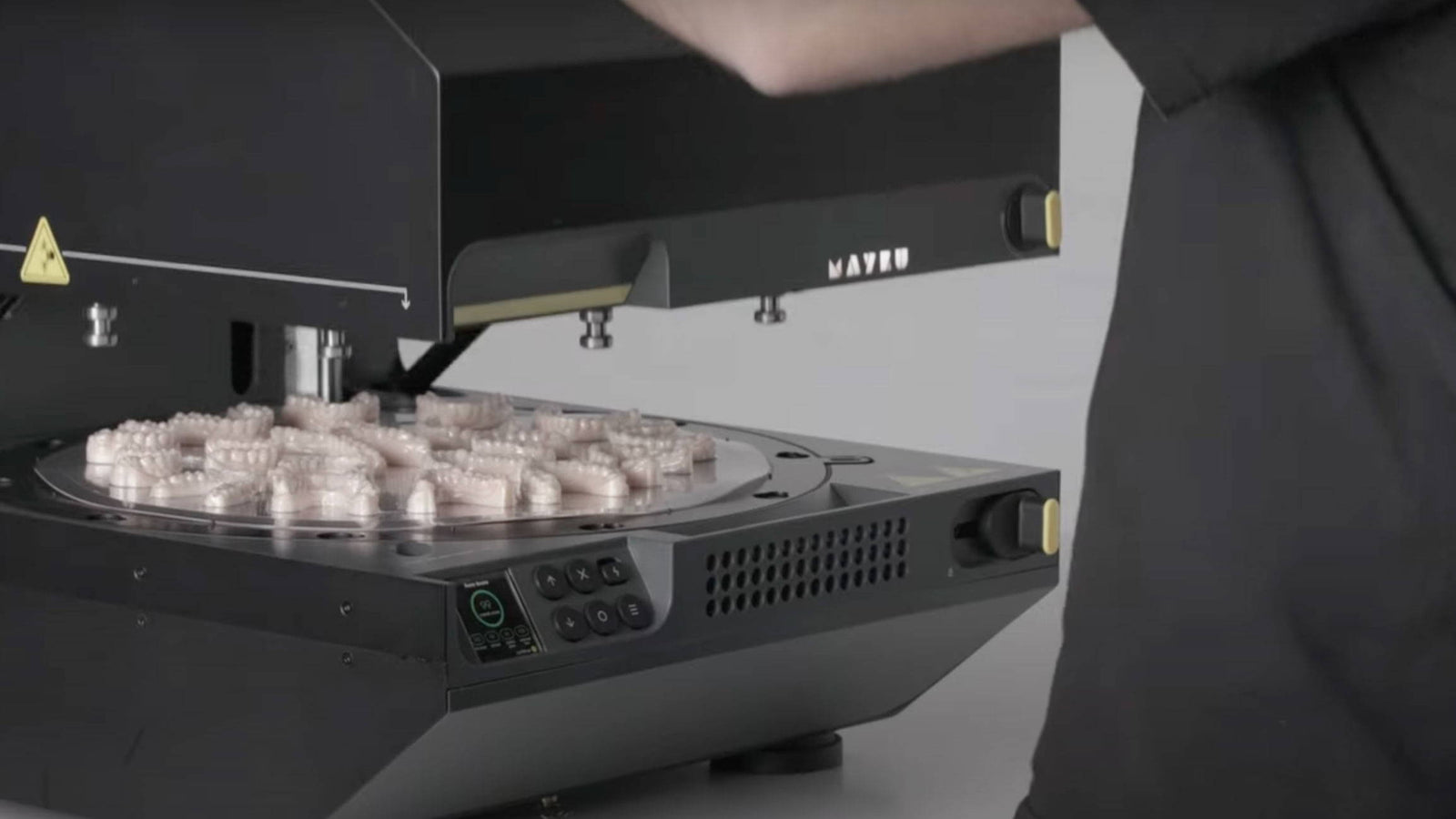

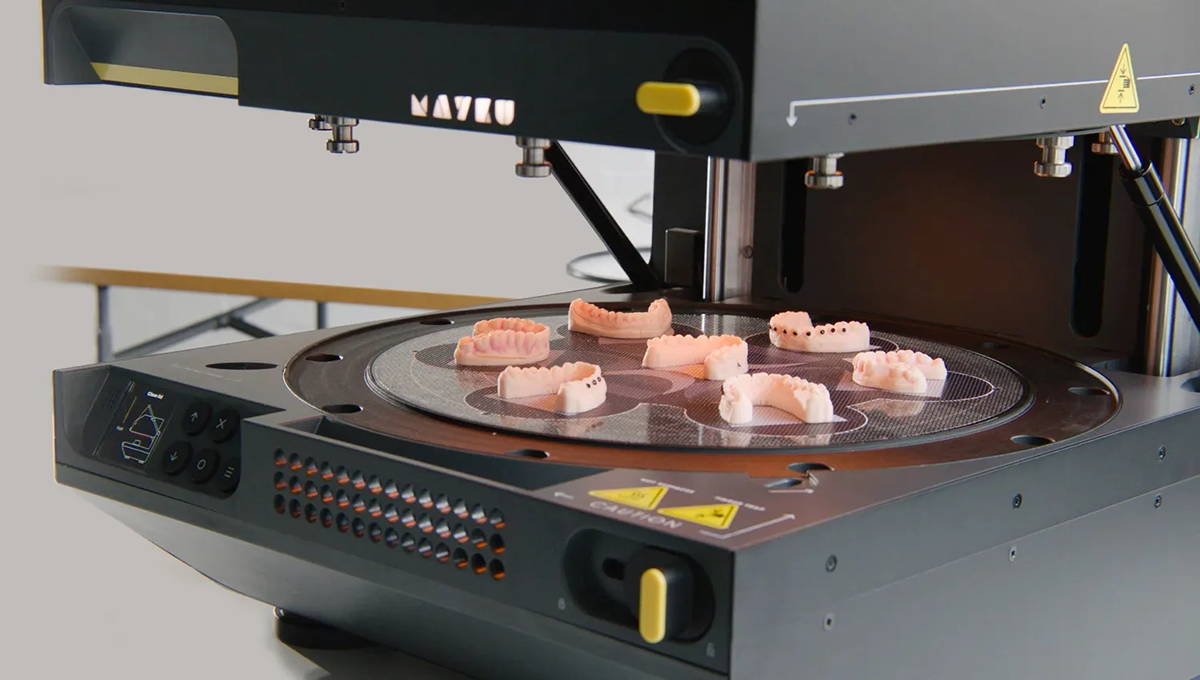

The Mayku Multiplier for Dental is a first-of-its-kind benchtop pressure former that achieves sub-one-micron resolution results in sheets up to 5mm thick. Such precision was once exclusive to industrial and laboratory equipment, but now being paired with high-resolution 3D printers, the Multiplier creates dental devices and parts that rival injection-molded quality, right from your desktop, within minutes.

Below, we have shared 3 case studies to help you better understand how the Mayku Multiplier is being used in the dental industries to save time and money, create stronger and better end use products and help labs increase their production capacities.

Case Study: Revolutionizing the Dental Hygiene Industry with Smile Brilliant and the Mayku Multiplier

Smile Brilliant is an innovative brand that delivers dental hygiene products like whitening trays and night guards directly to their customers and clients. Their mission is to offer high-quality, accessible dental solutions and they are utilizing the latest technology to boost product excellence and customer satisfaction. Leading their product development and innovation initiatives is Salman Shah, a company partner with a wealth of knowledge in automation, engineering, and cultivating relationships.

Case Study: Bridge Dental Uses Mayku Multiplier Technology for Innovation and Growth

Bridge Dental Laboratory is a family-run business that was created by George Wheeler's grandfather, and has been a long-standing provider in the dental industry. As the current lab manager for the laboratory, George Wheeler leads the company with a main focus on innovation and growth.

Their lab incorporated the Mayku Multiplier into their workflow and business which significantly enhanced their production capabilities. This new system enables the creation of up to 19 appliances in a single cycle when using the Mayku 428mm circular blanks. As a result, the laboratory has dramatically increased its output to serve more clients and is now producing 200 to 300 appliances per hour, saving time and money in the process.

Case Study: George Szekely Dental Lab is Increasing Productivity with the Mayku Multiplier

The George Szekely Dental Laboratory was established in 1968 and is currently a dental prosthetics facility owned by Janine Cerbu and her business partner Amha Selassie.

They struggled with a time-consuming production process for making night guards, essix retainers, aligners, and bleaching trays as well as a lot of difficulty managing high workloads, often requiring late-night and weekend work for employees

To address various work flow issues like these , the lab invested in the Mayku Multiplier 3D forming machine which is a much more advanced piece of equipment than they were used to and it is designed to improve efficiency and product quality for their lab.

Learn More About the Mayku Multiplier for the Dental Industry

Do you have questions about Mayku Multiplier for Dental? Feel free to reach out to us at info@shop3duniverse.org or visit our website by clicking the button below!