A Conversation with Erik de Bruijn of Ultimaker

June 08, 2023

Erik reflects on 3D printing collaboration, sharing, and the power of community.

Who's Who in this 3D Printing Conversation

Last week, Jeremy Simon of 3D Universe interviewed Erik de Bruijn of Ultimaker BV. Jeremy and Erik met at an e-NABLE conference at Johns Hopkins University last year, an experience that reflected their common interest in open sharing, collaboration, and community.

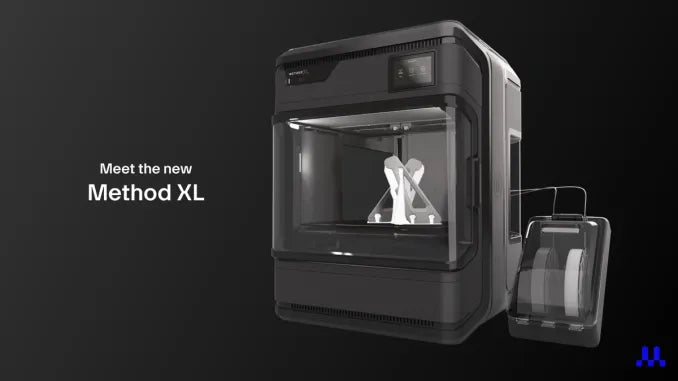

Erik de Bruijn is a co-founder of Ultimaker BV, launched in 2011. Ultimaker became an established brand in the 3D printing community within its first year, selling its flagship product, 'Ultimaker', to nearly 1000 people worldwide. The Ultimaker is the fastest 3D printer in its segment, printing the largest objects with the greatest detail.

Here's what the company has to say about itself:

"It all started with a thought. We wanted everyone to be able to enjoy the experience of making. Whether it was a cat dressed as an astronaut or a mechanical masterpiece, we set it as our goal to enable you to make those things. So we built a pioneering device that everyone could use and enjoy. We made it open source so everyone really could pitch in. And we started to grow 'We tinkered, tweaked, invented, innovated and reinvented. And so did our community'"

This statement reflects what became a theme of our interview: 3D printing is exciting, but just as exciting are the values the movement embraces. Tinkering, creativity, open sharing, collaboration, community, enabling and empowering: these are words we hear over and over again as 3D printing enthusiasts talk about the world of 3D printing, the world of tomorrow that is opening before us today.

The Interview, Part I: Erik de Bruijn's Role & Ultimaker, The Product

Jeremy: I'm here today with Erik de Bruijn, one of the founders of Ultimaker. Erik, can you tell us about your role with Ultimaker today?

Erik: We are growing rapidly. It's great to see so many new, talented people join the company. It is also great to know that although it's difficult for us to find the right people, we continue to find people who embody the Ultimaker spirit and share the same open source and open hardware ideals we have.

Although my role changes in some ways as we grow, in other ways my role as a founder remains constant, at least at its core: my job is to make sure our mission remains intact and that we can all do something we believe in. It is still very motivating to see people taking their ideas and making them tangible.

While I'm passionate about technology, I'm especially excited about technology as a tool: 3D printing, electronics, how they work together and how they can empower the user.

I learn from the people we're hiring. I like to connect various ideas and make something neat out of that. I'm able to do that with more and more people as we grow.

It's also my job to make sure we're working on interesting concepts and making good products. Our products are the driver in terms of what we can do in innovation.

Jeremy: Speaking of products, others have focused on making a machine that can reproduce itself, along the lines of the RepRap Project. Ultimaker seems more focused on quality. Can you talk with us a little about the commitments that make Ultimaker unique?

Erik: Yes, we are focused on making a printer that's high quality and reliable, but we do find that many people in the community are using Ultimakers to print upgrades for their Ultimakers!

We also want to make it possible for people without a lot of knowledge to use an Ultimaker. Things like layer thickness, quality control, repeatability, and resolution are very important to us. We want to raise the bar for desktop 3D printers. We're seeing now that our machines are used in medical research, for example, to make scaffolds for biofabrication.

It's these kinds of applications that, on the one hand, are a testimony to our quality and, on the other hand, push us to increase the quality of the machine and the 3D prints.

The Interview, Part II: Viability of Open Source Business Model in 3D Printing

Jeremy: Ultimaker has always had a commitment to open source. Some argue that it's difficult to maintain a viable business while giving away designs and maintaining an open source approach. How do you respond to that idea?

Erik: We do have that commitment, and we are viable and we keep growing.

Hopefully, people copy from us and contribute something back. We've seen a lot of people from the community improve and contribute to Ultimaker. Others have simply copied the machine and are selling these copies. This drives us to keep improving our machine.

Still, it's really about the kinds of interactions we have. There's a good feeling about what a community is and a sense of appreciation for why people are in this community. It's about tinkering and creating and sharing.

It's important to share what we know, not expecting something back but feeling confident that something will come back. The beauty of community is that we might get something back that we didn't expect! Or something for which we didn't even ask!

Publishing design files opens the opportunity for people with diverse skills to look at the designs and contribute. People look at the designs because they?re interested, but they might have a very different take, a diverse approach, and that adds to it.

Most companies look to hire a narrow set of people for R&D. That's the traditional way but probably not the best way to get an R&D department together.

The kind of community we work in doesn't have constraints around time or on what we can try. People have full autonomy, and that can lead to a process of creativity, to trying new things and experimenting.

Of course, there can be too much freedom as well as too many constraints. Balance is what we want. And so we appreciate different skills and give people free reign ? but we also have staff who make sure things are stable, who exercise quality control.

Taken together, stable quality and fast innovation is what makes a company viable. The open approach we take has proven to work well and benefits us and the community.

Jeremy: Erik, you and I met as volunteers with the e-NABLE community. Ultimaker has been very supportive of that community, donating printers, software development and more. Can you tell us about Ultimaker?s charitable efforts?

Erik: e-NABLE benefits from the freedom of 3D printing.

All too often, the goal of the medical community is to try to make a product like a prosthetic invisible. With 3D printing, you can decide what a prosthetic should look like. The recipient is in the driver's seat!

3D printed things, including prosthetics, don't only have to be useful but also cool and well-liked, or people won't use them. When a user can make the decisions, it's more likely they'll actually use the product.

And if they require changes, that can happen too, because a 3D printed prosthetic is so much less expensive than traditional devices. A 3D printed e-NABLE hand may cost $20. This makes it very affordable for the developing world as well. That's what I mean by the freedom of 3D printing.

Ultimaker wants to connect with that freedom. We used to develop things on the computer that remained virtual, but it's great to finally be able to make things physical, to invent something tangible by yourself or with others.

Also, e-NABLE is a community of people helping each other, so their orientation is similar to Ultimaker's.

The Interview, Part III: 3D Printing in Education

Jeremy: 3D printers are showing up in classrooms around the world. Ultimaker is a popular choice in schools. What are Ultimaker's goals with regard to education?

Erik: We are doing well in business environments, schools, and maker communities. We want to support these sectors because we came from them.

3D printing has been around for 30-35 years. In some ways, these environments are latecomers, and yet children are very creative. They'll catch the schools up fast, and we want to be part of facilitating that.

It's great for kids to have an idea and make it. Most of us grew up with the old idea that we ourselves can't make anything. The new idea is 'imagine, then make.' It's about dreaming AND doing.

3D printed items in the classroom can make ideas and concepts visible. A 3D printed depth map of Waterloo will let you understand why certain things happened at the battle. A 3D printed crown of an ancient king may let you see just how small people were back then. A 3D printed model of an engine lets you see how crankshafts work.

Especially for kinesthetic learners, 3D printing often makes ideas click much more rapidly than other methods. For experiential learners, 3D printed items in a classroom can also have a significant impact. These two learning styles are hardly addressed and taught to in the current educational system.

Imagine just sitting in a chair 30 hours a week with someone rattling off facts and concepts. Now imagine being a kinesthetic or tactile learner for whom touching and interacting with an item deepens understanding. For these kinds of learners, that lecture style of presentation is a very boring thing. 3D printing has a part to play in making concepts tactile and letting kids interact with a physical manifestation of an idea in order to completely understand it.

The Interview, Part IV: 3D Printing, Tinkering, Collaboration & the Power of Community

Jeremy: What is the most exciting experience you've had since starting Ultimaker?

Erik: That's a good question!

Probably one of the most powerful moments was at the e-NABLE conference at Johns Hopkins University. What a great event! All these people were using 3D printers and had been using them in their homes.

It was an amazing experience to see how all those parts for 3D printed hands were brought together. It was even more amazing to watch people assembling prosthetic devices with their children and for their children!

That experience made me feel proud of what we're doing as a company and as a community.

We have had moments within our own company as well. We feel an Ultimaker spirit with all these different people that have joined us. Of course, there are hurdles along the way, technological or interpersonal. The things that can sometimes be difficult are also the things that make it meaningful.

Jeremy: So really what you're doing is giving people a tool with these 3D printers. They take it from there, seeing what they can create. Have people done things that surprised you or that you weren't expecting?

Erik: I was just at an Ultimaker event a few days ago, lots of people coming together. A guy called Arjan showed me that he had modified his Ultimaker to add interchangeable print heads for multi-extrusion printing.

This process of expanding the capability of a 3D printer is what lets Ultimaker make better printers.

I think it would be ironic if people had a tool that can make almost anything but couldn't improve on the tool. I like coevolution. We shape the technology, and the technology shapes us.

Something big has changed since open source software became significant. We might not be able to find two people in the same geographical space and with the right set of skills to collaborate, but we can certainly find two on the globe. It's exciting. It finally gives us the power to collaborate globally and produce locally.

Jeremy: Where do you see consumer-level 3D printing going and Ultimaker fitting into that picture?

Erik: We are already in a steep growth curve, but there's still a lot of growth ahead before we hit the consumer stage. Still, I have to say, it's in the near future. We tend to overestimate exponential change in the short run and underestimate it in long run.

Certainly, we'll get to a place where we'll print different kinds of structures and materials with one device.

We'll see more people tinkering online with a design to make it work for them. We'll see more products completely manufactured to specification in this way. And collaboration tools will be more powerful too.

At Ultimaker, we want to encourage that collaborative process of tinkering and customizing. This possibility is a great motivator for me. People around the world can invent tools and have manufacturing capability in their homes and work with us. We cannot do it alone as a company – we want to collaborate!

The Interview, Part V: YouMagine

Jeremy: So I'd be remiss if I didn't ask for hints of upcoming product lines or initiatives . . .

Erik: I'm glad you asked. I'll mention a couple of things, but I'd like to focus on a project that is near and dear to my heart, YouMagine.

We're always working to make our machines more user-friendly, more capable and more connected. And we're working toward machines with multi-material capabilities.

The Ultimaker printer is an output device. It has to work well and be capable – but a single focus on a better device is too narrow.

We want to take things to the next level, so we work on lots of things at the same time. It cannot be just 'good' hardware if we want our users to succeed. Software and hardware need to work well together. This is where we can make a difference.

We also want to be sure the Ultimaker is compatible with materials we haven't even tried yet. That doesn't mean everything will work with it, but you have to have the freedom to use cutting edge material. And exciting materials are released almost on a weekly basis.

And there's YouMagine, a project I created and oversee. YouMagine is an online community of 3D printing enthusiasts who want to work together to share, remix and make better 3D printed things collaboratively. YouMagine facilitates this community, empowers and gives people the tools they need in order to improve, invent and make.

We believe that through collaboration and sharing all of us can make all the things better.

Jeremy: Erik, it seems as though the recurring theme of our conversation is the power of a community, of collaboration and sharing. This is what excites me about 3D printing as well. It's a new way of thinking and living and creating. Thank you for sharing your thoughts with us today.

Erik: Thank you. I enjoyed it.

Follow us on Twitter (@3dprintingisfun) and like us on Facebook. Subscribe to this blog, or visit us at shop3duniverse.com.

Learn about how we built a pair of Ultimaker 2 3D Printers HERE.

Learn how to get started with e-NABLE HERE.

More 3D Universe blog posts:

Learn how to assemble the 'tensioner' lines on the Cyborg Beast 3D printed prosthesis HERE?

My Cyborg Beast 3D Printed Prosthesis: Assembly and Testing post can be found HERE?

Check out my post titled ?Man Compares His $50 3D Printed Hand to His $42K Prosthesis? HERE?