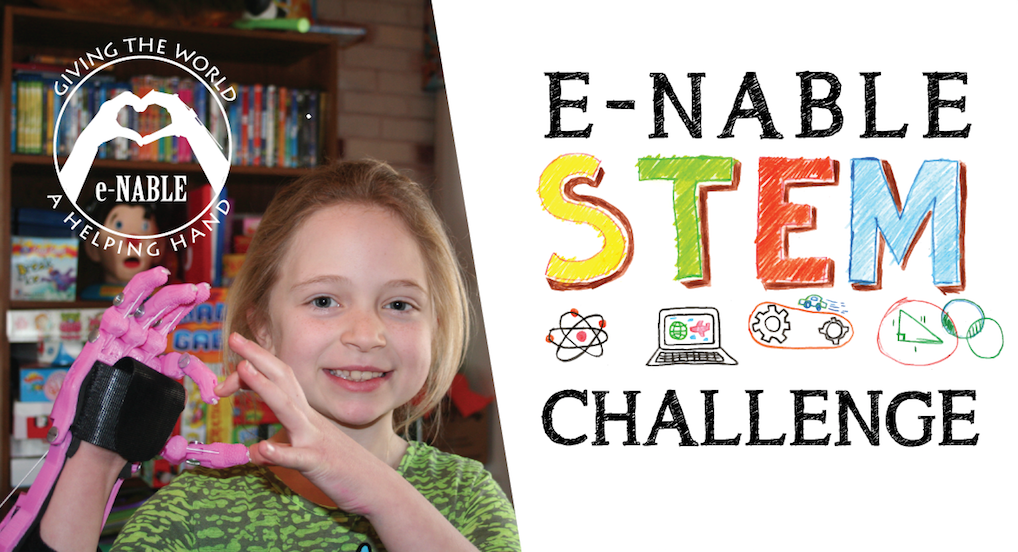

Introducing the Raptor Hand by e-NABLE

June 08, 2023

I had the rare privilege recently to work with a team of amazing individuals to help design the Raptor Hand by e-NABLE. This is the latest model of 3D printable prosthetic hands.

The 3D modeling work was done by Ivan Owen, Peter Binkley, Frankie Flood, and Andreas Bastian I provided project management and coordination, as well as 3D printing and testing of design iterations.

These guys are my heroes! I've been doing project management for over 20 years, but I've never witnessed a team work so effectively and efficiently as what I witnessed with this team.

They started with a blank slate, designed original 3D models for all the parts of the Raptor Hand, including many iterations and improvements - and all within a period of less than one month, on top of working their full-time jobs!

The Raptor Hand by e-NABLE was introduced at the recent Prosthetists Meet Printers conference with Johns Hopkins. Please check out Jen Owen's terrific blog post describing that event. I can't possibly describe it any better than she did.

The design this team came up with is truly elegant. A lot of thought was given to what worked best with previous designs, and where there were issues that could be improved upon.

The Raptor Hand is intended to bring together the best and most widely tested ideas from a year of crowdsourced innovation.

The objectives in designing the Raptor Hand were as follows:

- To simplify fabrication and assembly and repair for makers and recipients alike

- To provide a platform and reference design for future innovations, incremental and radical

- To identify a core features set and standardized dimensions embodied in accessible 3D models with progressive licensing terms that will ensure widespread availability and future development.

e-NABLE's prior 'go to' designs included the Cyborg Beast, the Talon hand, the Ody hand, and the Talon Beast.

To these classics, the Raptor Hand by e-NABLE adds the following features:

- Easier and quicker printing (no supports required)

- Easier and quicker assembly (no Chicago Screws required, simplified cord installation)

- An improved tensioning system (modular design, allowing for easier future development)

- Improved documentation (in progress)

All of the parts needed for assembly can be found easily in most areas. If you prefer to get everything in one place, 3D Universe offers assembly materials kits with all the parts needed for producing a Raptor Hand.

Instructions

The Raptor Hand instruction manual is in the process of being developed. Until then, please refer to the following video tutorial for assembly instructions.

Printing instructions:

- Print without supports (palm and gauntlet have some supports built into the model)

- Scale all parts as needed (the Raptor Hand is designed to work at scales from 100% through 170%)

- At 100%, the inside of the palm area measures 55mm

- Measure across the widest part of the palm, then add 5mm for padding, then divide by 55 to get the scaling factor (for example, if the palm is 65mm wide, then 65 + 5 = 70, and 70 / 55 = 1.27 - so your scaling multiplier would be 1.27 or 127%)

- PLA is recommended for this design

- Suggested settings are 0.2mm layer height, 35% infill, 2 outlines

- Refer to file names for part descriptions. The number in square brackets at the end of each file name indicates how many copies of that STL file need to be printed for a complete hand assembly.

Parts reference:

If you have a 3D printer with a large enough build plate, you can print all of the parts for an entire Raptor Hand in one pass.

STL files for printing a Raptor Hand can be downloaded from:

Thingiverse: http://www.thingiverse.com/thing:476403

YouMagine: https://www.youmagine.com/designs/the-raptor-hand-by-e-nable

Learn more about getting started with e-NABLE HERE.

Learn about e-NABLE Web Central HERE.

More 3D Universe blog posts:

Learn how to assemble the 'tensioner' lines on the Cyborg Beast 3D printed prosthesis HERE

My Cyborg Beast 3D Printed Prosthesis: Assembly and Testing post can be found HERE

Check out my post titled 'Man Compares His $50 3D Printed Hand to His $42K Prosthesis' HERE