Positive Ways 3D Printing Impacts Humanitarian Aid

June 08, 2023

Relief efforts for those affected by natural disasters or wars around the world are often frustrated by slow or failed supply chains. Meeting the challenge of attaining even the simplest necessities where and when needed is critical to success in the field.

Goods and supplies are usually funneled through various Humanitarian Aid Organizations and NGOs and too often arrive in one large delivery following the initial event.

This standardized response ignores local needs. It is a cumbersome approach to dealing with ongoing events and complications and leads to waste as well as voids in much-needed services and equipment.

A smart solution is to include 3D printers as an integral element in all emergency response team packages. The positive impact of easy access to 3D technology in the aftermath of a disaster is dramatic and effective. Here are four practical ways 3D printing helps humanitarian aid workers help others.

Nuts & Bolts

Real onsite disaster relief is often a matter of working with what is available and on hand at that time. Missing or replacement parts sometimes take weeks or even months to arrive, delaying progress where it is most needed.

Access to a 3D printer facilitates work in the field by allowing workers to get the parts they need printed on demand. The benefits of this immediacy include time efficiency and cost-effectiveness, allowing rapid rebuilding of infrastructure and communities.

Producing spare parts assures damaged medical equipment can be made functional again or missing tent spikes can be handily created to secure emergency shelters.

Much of what 3D printers produce, use recyclable plastics often conveniently available right there at the recovery site. It's a win/win for all those involved.

Simple 3D printed tools can make the difference between waiting to repair a broken-down jeep or moving on quickly to assist others in need. It's an expedient and portable resolution to the many challenges faced by emergency response and humanitarian aid teams.

Hearts & Hands

One of the most essential services provided by humanitarian aid practitioners is responding to medical needs. It is a primary concern after disaster strikes and can be logistically overwhelming.

Medical 3D printing had a profound effect in meeting the medical needs of victims after the catastrophic earthquake in Haiti in 2010. Innovative efforts by disaster relief pioneer, A. Dara Dotz, using 3D technology helped expedite the real-time demands of medical professionals trying to save lives.

Tarek Loubani, an emergency physician working in the Gaza strip, helped to create a functional stethoscope that can be printed for around .30 cents of plastic and shared the design as an open-source file.

Transportation issues are prevalent in disaster zones, and impassable and damaged roads sometimes make it impossible to get the life-saving medical equipment to hard-hit locations.

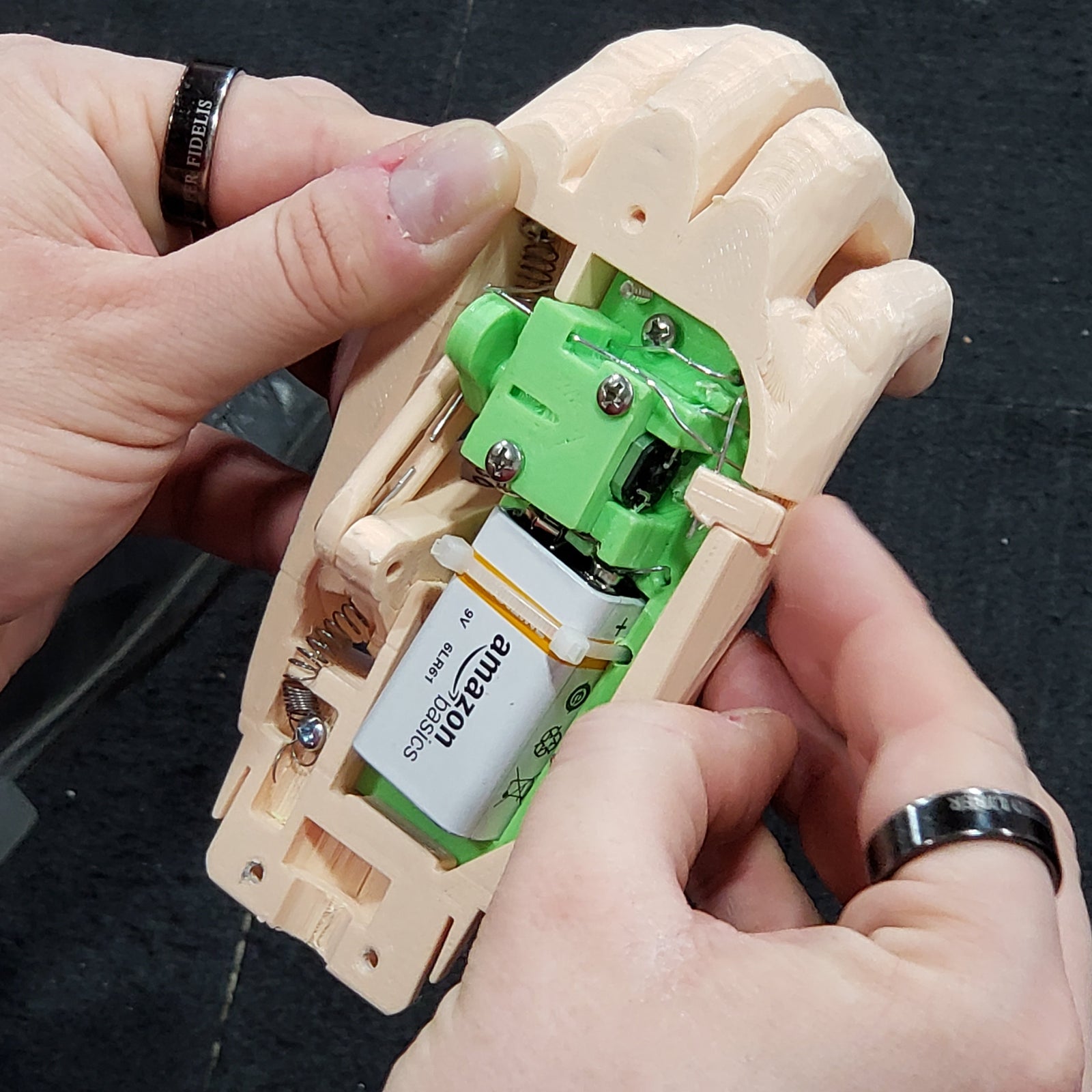

With 3D printing capabilities, technicians and field workers can print usable 3D printed prosthetic devices created by the e-NABLE Community and other charities, surgical tools, and other vital equipment necessary to treat patients and provide urgent care right on the spot. Working prototypes are being developed all the time, and future applications of medical 3D printing are promising and limitless.

Pipes & Water

Clean water and sanitation are often the biggest challenges in disaster-devastated areas of the world. Earthquakes, hurricanes, and tornadoes can destroy a community's infrastructure including its electrical grid and water system.

This was the case following the earthquake in Nepal in 2015 that left more than 200 families homeless. Unfortunately, the water pipes received to rebuild the system were lacking key components and complex plastic fittings. Aid workers did their best to patch leaking pipes with duct tape and anything else they could find.

Relief worker Andrew Lamb from the technology-based NGO, Field Ready, got busy designing new water fittings on his laptop. He connected the computer to a 3D printer using his car battery for power. It took two hours for the printer to finish, but the part fit perfectly and the leaking pipe was stopped.

The possibilities for identifying and creating needed materials in remote locations with 3D printing technology are endless. The Faircap project used 3D printing as a prototyping tool for its water filters offering a low-cost solution to dealing with contaminated water worldwide.

Home & Shelter

Housing and shelter for those left homeless after a disaster or in a war zone are usually arranged in the form of makeshift tent cities. It isn't the ideal situation since many of these tent communities end up becoming semi-permanent homes to those who have nothing left in the aftermath of catastrophe.

Housing charities like New Story in San Francisco are exploring ways of using 3D printing technology to print affordable dwellings in both disaster areas and in the poorest of the world's communities.

Transitioning displaced populations into secure housing using 3D printing is closer to reality though not yet on a large-scale basis. Organizations like New Story are envisioning and experimenting knowing the potential for success is right around the corner.

It will revolutionize the way communities fare and will encourage them to thrive once more rather than just survive. New Story has built houses for over 6000 people through traditional construction but hopes to do so much more in the future using 3D printing technology for humanitarian aid.

Considerations

With more frequent and severe storms causing havoc around the world, humanitarian aid is increasingly in demand. It's an expensive and labor-intensive undertaking especially in the more remote locations of the globe. Charities find their finances strained as they try to get supplies to where they are needed the most.

It only makes sense to take advantage of cost-cutting 3D printing options capable of using easy-to-recycle raw materials with very little waste. 3D printing technology will transform emergency response and positively impact the quality of people's lives.

3D Universe is Committed to Supporting 3D Printing for Humanitarian Aid

3D Universe has been committed to making 3D technology accessible to both professionals and beginners alike since 2013. 3D Universe is an active participant in the e-NABLE volunteer community which donates 3D printed prosthetic limbs to underserved communities worldwide.

We operate a donation program that allows us to provide assembly materials kits to our volunteers. Each donated kit allows one of our volunteers to produce one free prosthetic device for someone in need. We also have an e-NABLE Gift Card program, allowing you to help provide the materials our volunteers need to produce these free prosthetic devices.

Let us know how we can help.

Featured Image attribution: Julien Harneis