How 3D Scanning and 3D Printing are Being Combined to Improve Product Development in the Manufacturing Industry

November 09, 2023

3D scanning and 3D printing are revolutionizing the field of product design and manufacturing. These two technologies, when combined, create a seamless process that allows for rapid prototyping, customization, and improved quality control. The integration of 3D scanning and 3D printing technologies has opened up new possibilities for product designers, engineers and manufacturers, enabling them to create products that were previously impossible or too costly to produce.

What is a 3D Scanner?

A 3D scanner is a device that analyzes a real-world object or environment to collect data on its shape and possibly its appearance. The collected data can then be used to construct digital three-dimensional models. It works by projecting a beam of light onto the surface of the object and then measuring the distance and angle of the light that is reflected back. This information is used to create a "point cloud" of data, which represents the surface of the object.

There are several types of 3D scanners, including laser scanners, structured light scanners, and photogrammetry. Laser scanners work by sending a laser beam onto the surface of the object and measuring the time it takes for the light to return to the scanner. Structured light scanners, on the other hand, project a series of linear patterns onto the object. By observing the deformation of the patterns on the object, the scanner can calculate the distance to specific points on the object.

Photogrammetry, while not a scanner in the traditional sense, is a technique that uses multiple photographs taken from different angles to create a 3D model. Sophisticated software can analyze the differences between the images to calculate the distance to points on the object, creating a 3D representation.

Regardless of the type, most 3D scanners work in a similar way. They start by projecting a light source onto the object to be scanned. Sensors in the scanner then measure the reflected light and use this information to determine the distance and angle from the scanner to the object. This data is then used to create a digital 3D representation of the object. This digital model can then be manipulated, analyzed, and used in a variety of applications, including 3D printing, virtual reality, and computer-aided design (CAD).

How is 3D Scanning Being Used with 3D Printing in Manufacturing?

3D scanning technology is particularly useful in product design and manufacturing because it allows designers to capture the exact specifications of an existing product or prototype. This digital model can then be used to create a 3D printed replica, or it can be modified to improve the product's design. This process significantly reduces the time and cost associated with traditional product design methods, such as manual measurements and hand-drawn designs.

On the other hand, 3D printing, also known as additive manufacturing, is a process that creates a physical object from a digital design by layering material until the object is formed. This technology has revolutionized manufacturing by allowing for rapid prototyping, which enables designers to quickly create a physical model of a product for testing and evaluation. Furthermore, 3D printing allows for customization on a level that was previously unattainable with traditional manufacturing methods. Designers can easily modify a digital model and print a new version of the product, allowing for a high level of customization without the need for costly and time-consuming retooling.

The combination of 3D scanning and 3D printing technologies has also improved quality control in product design and manufacturing. With 3D scanning, manufacturers can create a digital model of a finished product and compare it to the original design to ensure accuracy. Any discrepancies can be identified and corrected before the product goes to market. Similarly, 3D printing allows for precise control over the manufacturing process, ensuring that each product is produced to the exact specifications of the design.

The integration of 3D scanning and 3D printing in product design and manufacturing has led to significant advancements in the field. These technologies allow for rapid prototyping, customization, and improved quality control, making the product design and manufacturing process more efficient and cost-effective. As these technologies continue to evolve, we can expect to see even more innovative and high-quality products being produced.

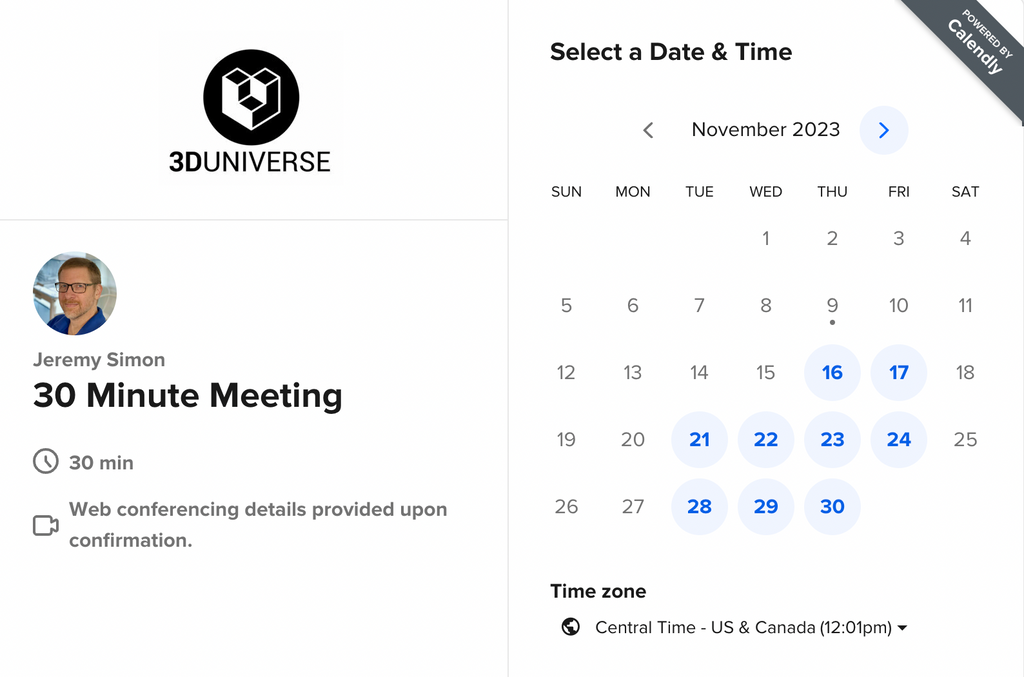

Learn More With a Free Consultation!

Have questions about 3D Scanners or any of our 3D printers, laser cutters, filaments, or forming machines in our shop? Consider booking a one-on-one Zoom meeting with Jeremy for a free consultation! Click here to schedule a discussion.